Many years ago I made a nice table for my son and his family and shipped it to their home in New York. It was made in San Diego in mid-summer without allowing for wood movement. Needless to say, the table did not survive the first winter of cool temperatures and indoor heating in New York which produced shrinkage, a large crack in the top and a painful but valuable lesson for me.

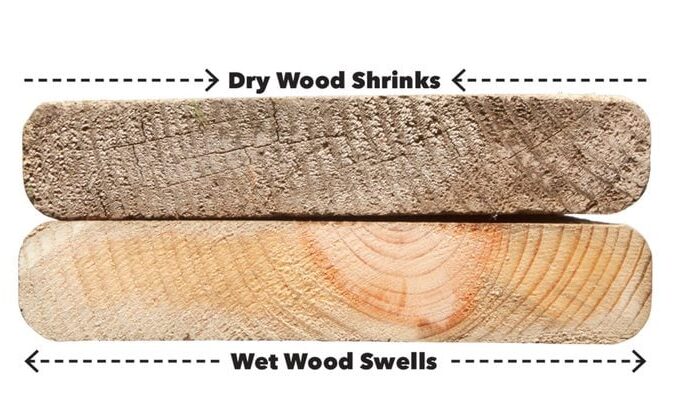

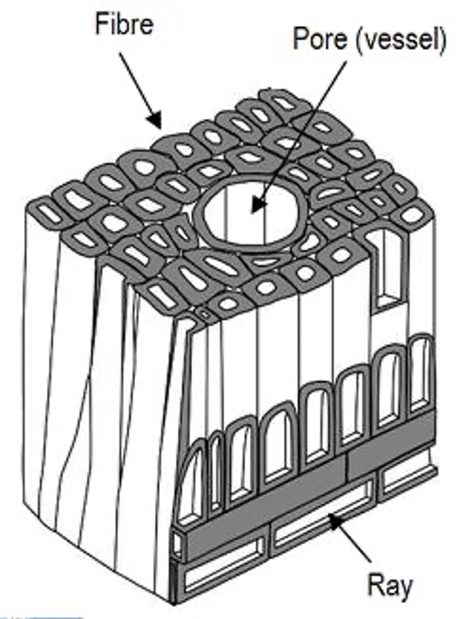

Here is some information about how to predict wood movement and techniques to protect your work from the damage it can do. Wood shrinks and swells in response to changes in its moisture content. The complex structure of wood consists of microscopic cells, solid fibers and hollow pores. The details vary greatly according to species but a simplified picture looks like this.

Palomar has a great article on wood structure at this Internet address: http://waynesword.palomar.edu/trjuly99.htm When a tree is felled, the water held within the pores and cells (“free” water) and in the walls of these structures (“bound” water) can account for anywhere from a third to twice the weight of kiln dried lumber. After all the free water in pores and cells has evaporated, further drying results in shrinkage.

Moisture content of Kiln dried lumber is as low as 10%. Left to dry naturally in open air, wood eventually reaches equilibrium with its environment and, over time, will gain or lose about 1% of its moisture for every 5% change in relative humidity. Relative is important because the actual amount of moisture that air can hold depends on temperature – less in hot environments, more in cold ones.

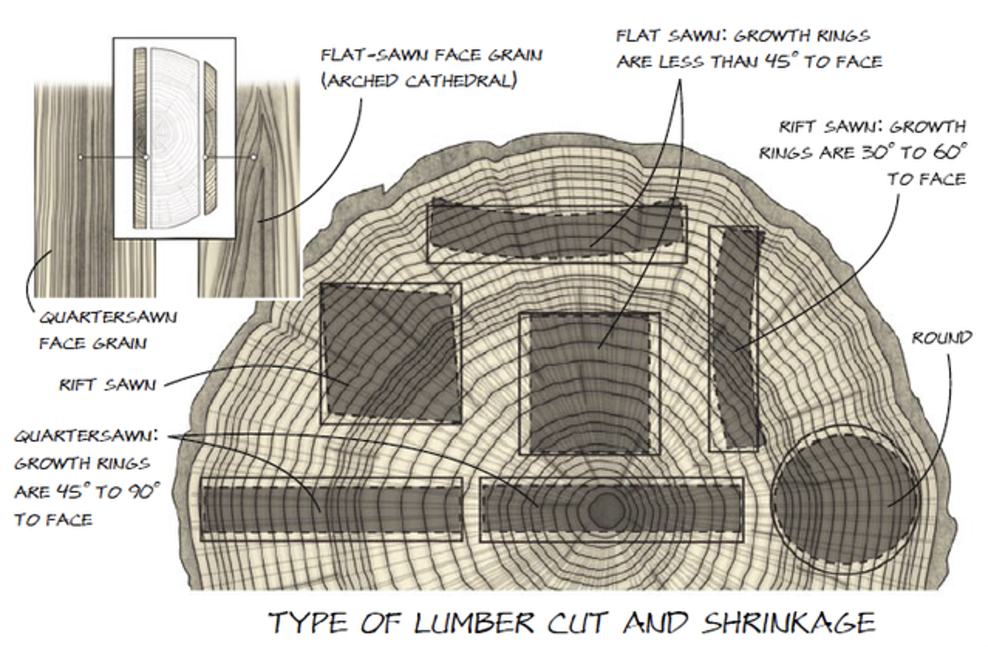

All wood swells or shrinks and also changes shape as it gains or loses moisture. These changes vary by species and depend on how the lumber is cut. Longitudinal movement (parallel to the grain) is minimal and can usually be ignored. Radial movement across the grain (tangent to growth rings) varies according to how the log was sliced; greatest in flatsawn lumber, least in quartersawn, intermediate in rift sawn.

Shape changes also vary according to how the log was cut as shown in this diagram.

The direction of cupping can be predicted by looking at the grain pattern in the cut end of a plank. Cupping always occurs in a direction that tends to straighten the growth rings. Cupping, twisting, bowing, etc. are also most severe with flatsawn lumber, least in quartersawn and intermediate in riftsawn.

Here is a short list of common domestic species in order of lowest to highest change in size (average change of a 12″ wide plank in inches) due to change in moisture content: Cherry 0.12, walnut and ash 0.13, poplar 0.14, birch 0.16, maple 0.17, oak (red & white) 0.18

Many charts with values for more species and for calculating expected wood movement are available on the Internet. Most are too complicated for discussion here but there is an excellent article in FWW #241, August, 2014 with a chart and explanation how to do the calculation. For the chart on the right, multiply the number given by 10, then by the width of your plank in inches. If you prefer fractions multiply the final number by 16 (or 32, etc) to get an approximate change in 16ths of an inch.

If you plan to calculate movement to be expected for specific changes in humidity, you will need a moisture meter. They come in two forms; pin or pinless. The pin variety allows remote readings and can measure at some depth but requires sticking two pins into the wood; not desirable for testing finished wood or in a lumber yard. Pinless meters require a smooth, flat surface and good contact for accuracy. If you are concerned about marring your wood, a pinless meter may be best. If you dry your own wood or use wood thicker than 2 inches a pin meter is more appropriate.

Meters for woodworking range in price from $15 at Harbor Freight to $350 for a highly rated Ligno Mini ED meter, available at Rockler for $119 and rated “Best Overall” in FWW #210, February 2010. An Electrophysics MT90, available on eBay for $69, was rated “Best Value” in the same article, Another well reviewed choice is the Delmhorst J-Lite meter which retails for $169. Higher priced meters come with temperature correction and/or species correction; very useful features.

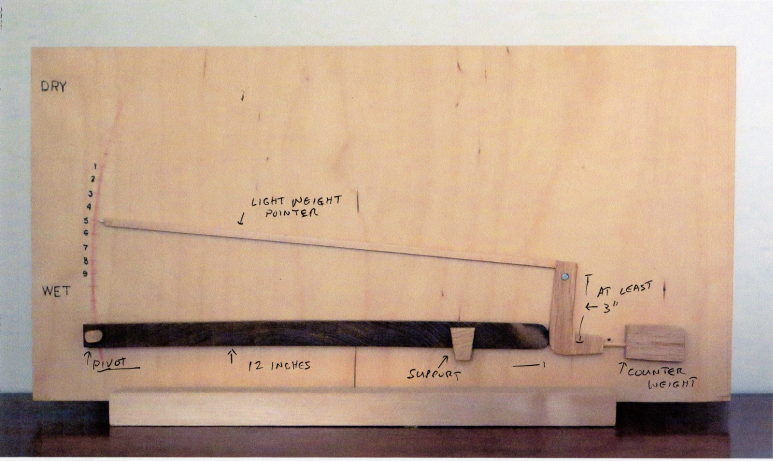

Wood responds slowly to changes in the environment. You can get an indication of what has actually been happening to the wood in your project by watching a small strip of wood suspended so that it moves a pointer as it shrinks or expands. This gadget is one I made.

The climate where you work plays an important role in the amount of movement to expect; the more variation in temperature and especially humidity, the more wood will move

Here are some facts about humidity in San Diego where relative humidity typically ranges over the course of the year between 42% and 87%, rarely going below 17%, sometimes as high as 100%. The most humid weather occurs between July 30 and August 30, when the average daily high has averaged between 64% and 87%. Our driest weather, in early December, averages relative humidity below 58% on three days out of four.

What practical steps can be taken to make practical use of this? First, be aware of the classic situations in which wood movement can cause trouble. They all have in common the need to join parts with opposite grain direction: 1. frame and panel doors 2. breadboard ends 3. wide (over 3″) mortise and tenon joints 4. solid wood table tops 5. web frames and drawers guided in a chest or cabinet 6. solid wood drawer bottoms 7. moldings and cornices.

Here are some suggestions gleaned from in two good FWW articles; #165, September 2003 and #255, July 22016.

1. Frame and panel – leave appropriate size gaps all around, glue only the center of the end grain edges of the panel and do not glue the long grain edges.

2. Breadboard ends – glue only the center of the joint and create appropriate size slots for the screws or pins at the ends.

3. Wide mortises – when over 3″, only apply glue to the upper third of the mortise and leave a small gap at one end of the mortise.

4. Solid table tops – use one of several styles of metal screw fasteners which allow for movement or make “buttons” screwed into the top that connect with small slots in the aprons.

5. Web frames – mount the cross grain part of the frames in a dado and apply glue only to the front end and leave room in the back mortise.

6. Solid drawer bottoms – orient grain to run side to side, leave space for expansion under the drawer back and do not apply glue to the side edges of the bottom.

7. Moldings – attach to the sides, not the top, only glue one end and use light weight nails for the rest.

Now you are ready to produce work that should last many decades or longer.

By Dick Ugoretz (originally published on November 2016)

Editor's Note: Light edits have been made to remove broken web links.