By Tim Peachey

The design is heavy on CAD and use of the CNC router, mainly because of career background, tools in hand, and personal preference. It is over-engineered and far more complicated than is needed for patio furniture, but now that the design is complete, it is easy to modify if needed, and easy to replicate. But then again, how many patio tables can one use?

The leg design is clean when finished, and strong. First, the legs connect to the stretchers using an interlocking half lap joint. This joint is self locating, and uses only glue for attachment. There are no fasteners anywhere in the table. The “jigsaw puzzle” style interlocks very accurately to locate the pieces and add strength to the joint.

Figure 1. Interlocking Half Lap Joint

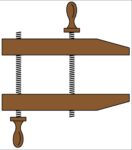

After forming two U shaped pieces made up of two legs and a stretcher each, they are connected in an interlocking crisscross strengthened with splines. This is an idea borrowed from The Wood Whisperer on YouTube, and modified to make it easier to create the spline cutouts on the CNC router.

Figure 2. Exploded View of Splined Crisscross Joint

Again, the parts self align and only glue is used to put them together. The lack of a “skirt” makes for more leg room.

The tabletop follows a similar approach. Eight rim pieces interlock and two crossed members provide the structure and nesting sockets for the table boards. The table boards nest rather than interlock because interlocks aren’t needed and would likely cause fit issues thanks to tolerances and the variability of wood.

Figure 3. Interlocking Rim of Table Top

Figure 4. Partial Assembly of Bottom of the Tabletop to show Structure

Figure 5. Fully Assembled Top, Upside Down

While the design was a lot of fun and built on ideas from multiple sources and things learned on earlier projects, actually building it was most enjoyable. Yellow Cedar 2x6s with a bit of milling made the fit much better, and the worst parts of the lumber were sorted out while leaving in a few knots because it was impossible not to. The table is finished in several coats of boiled linseed oil, and will be re-oiled each fall before storing it out of the elements for the winter here on Vancouver Island. The top and the legs are aligned using a dowel, and lift apart for transport and storage.

Figure 6. Finished Table

Observations and Lessons Learned:

- It is important to get the fit correct. CNC is very accurate and there is a tendency to make things fit tightly. The planned gap between mating parts needs to not only consider tolerances and the variability of wood, but applying glue can cause local swelling before all parts are assembled. A good dry fit is important, but sometimes a good dry fit is too tight when glue is added.

- A parametric design approach is a bit more complicated, but the design is now very easy to modify and scale. For example, the wood thickness was 35mm, but could be changed to 30mm in seconds with all features and CNC code automatically updating. Heights, widths, angles, etc, can be easily modified. The design was “toyed with” repeatedly to try to see what dimensions and angles would be pleasing, fit the available material, and result in the size of table needed.

- The splined crisscross joint aligns well in assembly and is very strong. But considering transport and winter storage, it might be better to develop a version of the leg structure that comes apart and takes up less space. Strength would be compromised, but with 2×6 stock there is strength to spare.

- The gaps between boards look nice in the tabletop, but dealing with glue squeeze out was a challenge. Titebond III was the adhesive used because of its ability to handle rain, but its colour made bits of glue in little gaps a challenge. An oscillating tool was useful reaching dried glue.

- This design hides the interlocking joints. But it would also be possible to feature these joints by bringing them to the surface.

- The assembly steps shown in Figures 1 and 2 can be reversed in order. In previous applications of this approach to smaller tables, the crisscross stretchers were assembled and the CNC router used to make a centred spline. The legs were added after the crisscross was complete.

- Several parts required CNC machining on both sides. This wasn’t difficult to achieve with alignment pins.

If any member is interested in having the Fusion 360 design, it is available to be shared. A short session to explain details would be useful to the recipient.

Editor’s Note: Learn more by way of his post in our Member Forums.