by Tom York

(Fourth in a series on Super Volunteers)

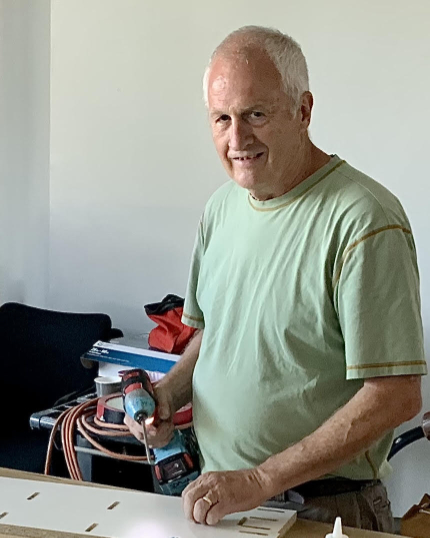

A half dozen men and women scurry about the spacious new bench room at SDFWA’s Member Shop. Two wrestle to re-hang a hand tools cabinet on the rear wall; another two cut and trim and then place the white tiles needed for the kitchenette.

The tall man in workmen’s clothes directing the workers takes scant notice. He’s too busy with other activity, lost in the details of ongoing construction.

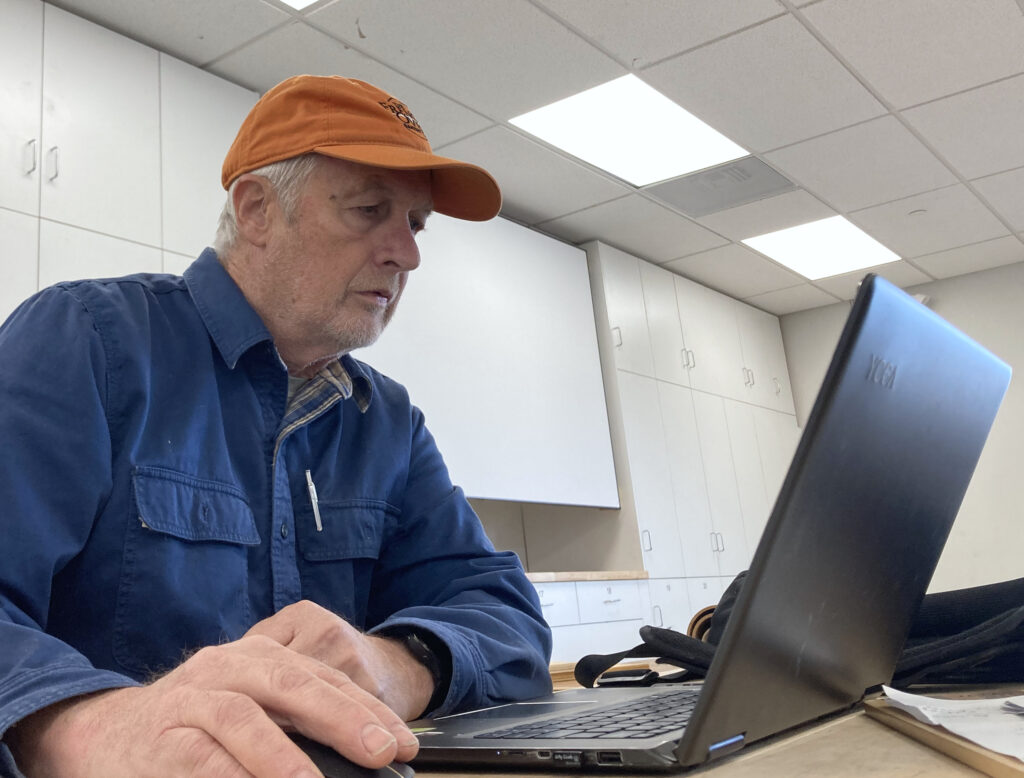

Peering into his laptop, he is plotting the next series of steps in this project, what everyone in the club knows as the Shop 3.0 expansion, now entering it final phase of construction after a year and a half.

The ambitious effort, all undertaken by shop volunteers is two-thirds complete. So, far it’s all has been accomplished with the help of the dozens of volunteers who have made it happen.

The man at the laptop, super volunteer Rick VanHatten, has been the driving force behind the expansion from the get-go, coordinating all of the many tasks with peripatetic Shop Director Dallas Keck, who has been on site nearly as much as the project progresses.

Rick has brought a deft touch to the overall planning and execution, especially in his ability to use the experience and talents of the volunteers.

One of his most impressive skills—and he has many–is the ability to direct those steady stream volunteers who show up three days a week, ranging from those with little to no experience to master carpenters.

Each one walks away contributing a piece to the overall expansion. They each can say, “I helped build that.”

“They take pride in their contribution to the overall effort,” he said.

How does he do it? Three days a week, Rick divvies up the work into various tasks from complicated to simple, so that even volunteers with minimal skills can make a valuable contribution to the project.

But those volunteers have finished three complex projects to date, starting with the meeting and laser rooms the upstairs suite and recently the new and improved bench room.

Rick brings a rich background in engineering and construction to the project.

Surprisingly, for a person who has given so much to the expansion, he’s a somewhat of a newcomer to SDFWA–having joined just four and a half years ago after relocating here from the Bay Area.

Rick grew up on a farm in South Dakota, where he says he gained much of his early expertise in woodworking from working in a lumber yard during the summers and for a contractor during college. Rick is proud to say he’s owned a table saw since college. “On the farm we didn’t have money to pay someone to fix things so you figured out how to do it. Just because you don’t know how to do something doesn’t mean you can’t do it.”

He attended South Dakota State University, then worked for an electric utility as an electrical engineer in Iowa and over the years in all phases of power generation, transmission, and distribution. Toward the end of his career, after leaving the utility he worked for a protective relaying manufacturing company starting up a consulting branch in northern California before retirement in 2017.

Rick says he and his wife, Wendy, wanted a change of scenery when he left the utility and figuratively rolled the dice.

“We wanted to live in an environment where there was only one door to open—not two when we went out to shop or eat,” referring to the double doors required in most commercial establishments to keep out the cold, ice, and snow of winter.

“We literally put pins on a map to find a place with nicer weather, and landed in California. Quite the change after spending our entire life in the upper midwest”

In 2008, they moved to Vacaville north of San Francisco. After retirement our son and his wife asked us if we wanted to build a house on their property, which brought us to San Diego. Two grandchildren made the decision easy.

Rick built a 1200-square-foot home on his son’s property, doing much of the construction himself, including construction of a custom kitchen, self-made cabinetry included.

He’s proud of what he accomplished in his home– eager to show pictures of the finished work.

But these days, Rick is taking the same pride with he and his volunteer teams have accomplished with expansion 3.0.

Despite the wide range of volunteer talent, the finish product is no less than professional looking, and in fact, quite impressive.

It’s obvious to the casual observer that professional crews could not have done a better job. The level of work is that high.

Indeed, Rick says the cost of the project has been a third of what it would have cost had the club hired outside contractors to perform the work.

“We have been able to save a lot of money.” That keeps expenses down, money that can be put back into the operation of the shop.

Rick says the steady stream of volunteers have shown up for workdays held Tuesdays, Thursdays and Saturdays. He estimates that as many as 70 shop members have given time to the project, including a small cadre of “regulars” who show up on a consistent basis.

“We’ve always seemed to get the right number, not too many and not too few,” he says. “We’ve been able to keep everyone busy.

Before joining the member shop, new members, including those graduating from the SDWFA’s popular Intro to Woodworking course, must agree to volunteer for the club.

That stipulation has helped bolster the cadre of volunteers over the past 18 months.

“I have seen a lot of new members show up on our volunteer workdays,” he said. “They want to do good work; they want to feel good about it. They take pride in what they do, and the helps to get a quality product.”

Rick attributes the success so-far with 3.0 to another experience at a large volunteer project in Iowa. When he lived in Sioux City, he participated in a mega-volunteer project, to build-out of 16 private soccer fields.

Meanwhile, 3.0 is heading to a conclusion—the final phase is tearing down the wall between the shop and the old bench room, then spreading out the machine tools to give members more room to work, he says he be scaling back his commitment to spend more time at home and working on his own projects.

Despite the demands on his time the past 18 months, he has his wife Wendy managed to take time off, including a two-week vacation last fall—a trip to France. The couple are planning another visit this spring.

But he needs to get back more personal time. He says he’s become “indebted” to the house, and needs to catch up on chores put on hold while 3.0 has been underway.

Everyone is most appreciative of Rick’s work, especially the club leadership. Dallas Keck says Rick has been the driving force behind the success of the 3.0 buildout.

“Rick’s leadership style is calm and steady, yet always focused on what’s most important,” says Dallas. “He’s fostered a core of volunteers who have devoted an amazing amount of time, energy, and skills to make shop 3.0 a reality.”

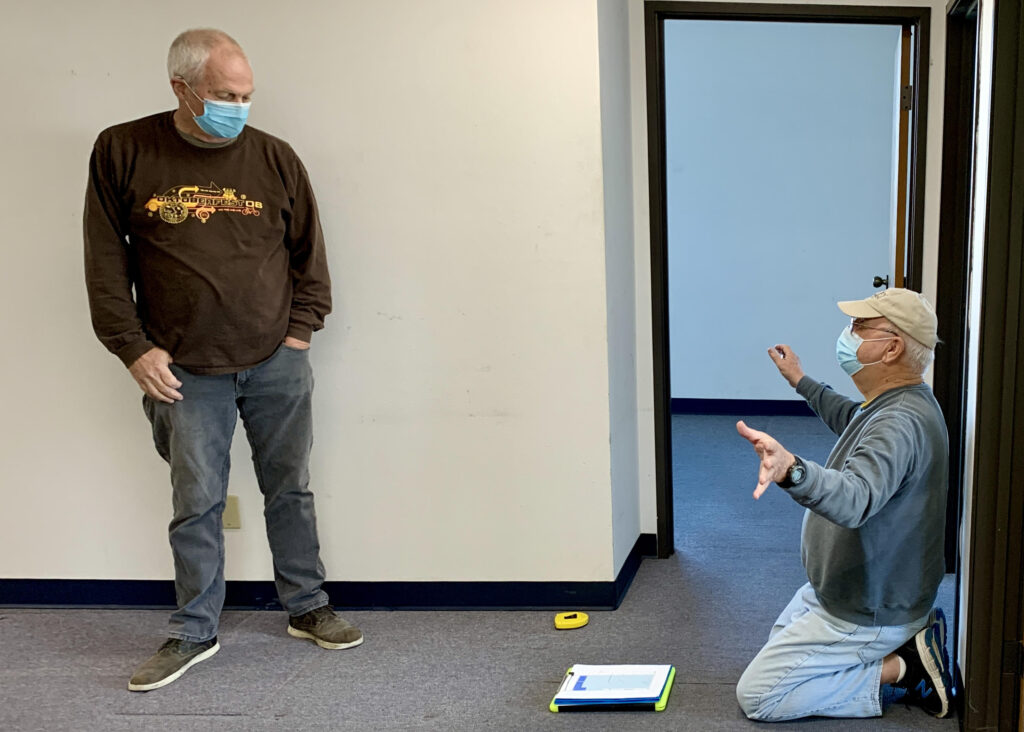

“It’s not unusual to see Rick patiently coaching a new woodworker through the process of solving a woodworking problem,” adds Dallas. “When I first met Rick I knew he was going to be a wonderful addition to our woodworking community. What I didn’t know was how he would become one of my closest friends.”

Written by Tom York

Author of our “Super Volunteers” series.

Daily newspaper reporter and editor for years and years.