SDFWA Woodturning Operations

Woodturning is a physical activity, which requires not only rote memorization of safety procedures but also enough practice using good tool technique to establish muscle memory. The shops wants to assure that members can work independently on any of our lathes and do so safely, with respect for the lathes, tools and accessories provided. Mistakes can be injurious and must be constrained when there are other members nearby and liability concerns are significant.

The Shift Supervisors are not, for the most part, experienced wood turners and are not always able to provide safety monitoring in the wood turning area. Each member turning in the shop must follow the SDFWA Member Shop Lathe Guidelines and be aware of possible dangers that could affect themselves and other members present in the shop. High speed flying projectiles can cause significant damage.

Lathe Certification:

Members who have recent woodturning experience, as defined in the “Lathe Guidelines”, can be certified to independently use the shops lathes by completing a short written test and meeting with a Lathe Certification Volunteer to demonstrate their understanding of the Guidelines and their ability to operate the lathe safely, with sufficient safe tool handling, proper care of shop gouges, tools and equipment. The evaluation will show how the member will choose and prepare stock, setup the equipment, safely mount the stock, properly sharpen selected shop tools and show safe tool control while turning.

Documents

SDFWA Member Shop Lathe Guidelines Link

Lathe Safety Test ( Print and complete answers)

Currently there are two levels of certification being evaluated as defined in the Lathe Guidelines.

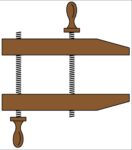

- Spindle Turning

- Basic Bowl Turning

If there is a safety concern observed during the certification process:

- The evaluator can instruct and follow-up with observed proper use.

- If the evaluator feels the member cannot turn safely in an unsupervised shop environment, the member will not be certified and a recommendation will be made to complete further training and/or mentorship.

If you feel that you are qualified to turn in an unsupervised shop setting and want to complete the Certification process, please contact Mary Russo at maryprusso@gmail.com to be assigned an evaluator. Complete the written test and bring it with you to your scheduled evaluation.